HOW IT WORKS

FirstLook: How It Works

This section will explain how the FirstLook® sensor works. You can also read the manuals for the ADS ES 100 sensor. To make the understanding easy, we have provided you with the video demonstrations. If you are one of those who prefer visualization than just reading the articles, then it will show you how easy it is for you to use FirstLook® sensors in your day-to-day operations. You can also go through case studies to get a better understanding of the FirstLook® operation.

FirstLook® Theory of Operation:

The FirstLook® sensor looks at the pulse waves generated by the normal operation of an internal combustion engine.

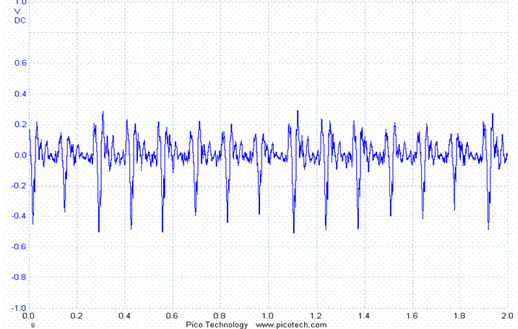

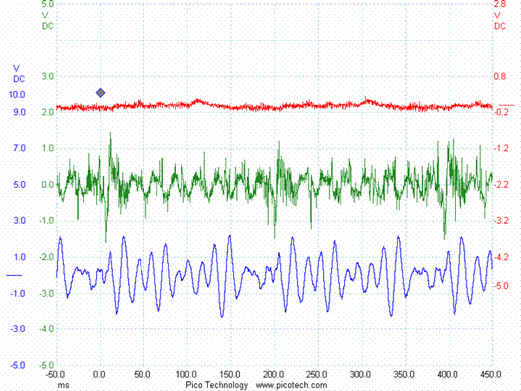

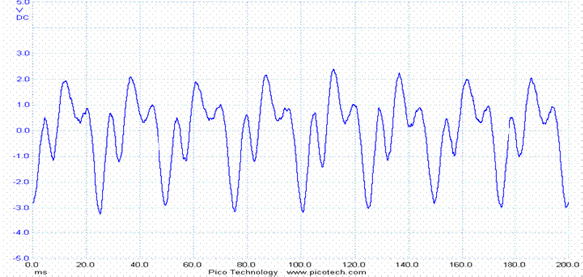

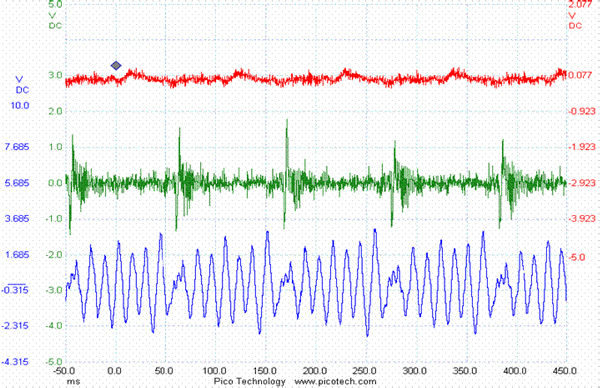

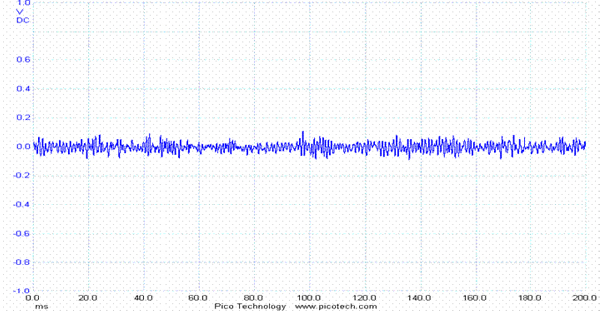

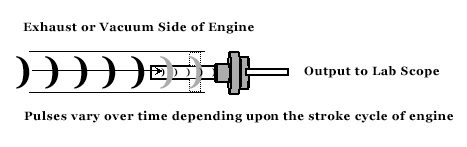

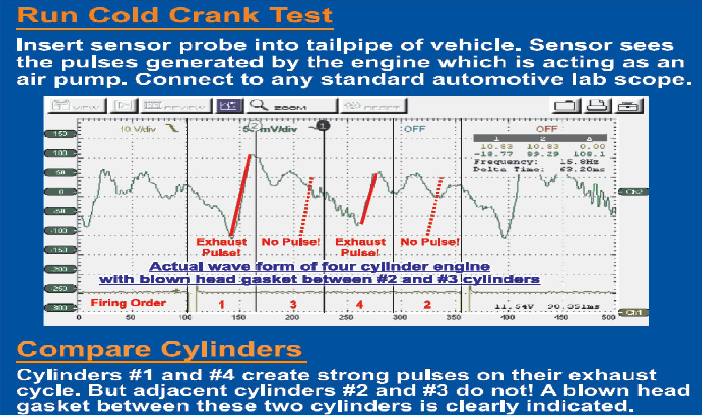

The Engine air flow produces a series of high pressure pulses separated by low pressures. Intake valves and exhaust valves open and close in a specified order with a specified timing. A ‘pulse’ of high pressure air is pushed into the exhaust system every time a cylinder’s exhaust valves open. The sensor detects these pulse waves through either the exhaust or vacuum side of the engine, or through the oil level indicator tube where pressure changes can be caused by ‘blow-by’ around the cylinders and rings. The pressure signature shows the events that occur during the 4-stroke cycle and when in the cycle those events occur. In a perfect engine, the pressure pulses will all look the same and be equally spaced. Engine problems will show in the pressure signature. Abnormal pressure pulses will jump out at you. And the shape of the pulse will tell you what is wrong.

The key to this is FirstLook®’s unique pressure sensor design. This consists of a piezoelectric material in a patented protective housing assembly. The piezoelectric material “measures” the pressures in the air flow in which it is placed.

Why It Works

All materials deform under a load. They compress or bend when the pressure on them increases. They expand or relax when the pressure on them decreases. Some materials, such as rubber, deform easily. Other materials are harder to deform, but they still deform.

Piezoelectric materials produce an electric charge as they are deforming. This electric charge is approximately proportional to the pressure on the material. As the pressure increases, the deformation increases and so does the electric charge.

Piezoelectric materials can only be used to measure dynamic pressures, pressures that are changing. They cannot measure static pressures. The material stops deforming once the pressure becomes static, or constant. Now, the material is no longer producing an electric charge. And the electric charge that was produced bleeds away to zero because of the conductivity of the material. Fortunately for us, air pressures in a running engine are continuously changing.

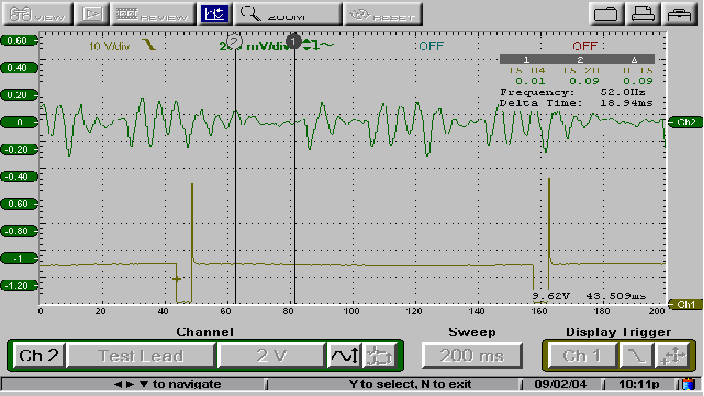

Internal combustion engines produce a predictable pattern of these pulses which can easily be displayed on most commercially available lab scopes when connected to FirstLook®. This pulse wave is sensed and the voltage is output for display by the lab scope. Any change or irregularity in this predictable pattern can be traced back to problems in the engine. The pulse wave can also be affected by unburned fuel in the exhaust and this abnormality is also detected and displayed. The FirstLook® sensor does not require any external source of power, so you never need to purchase or replace batteries.

Care for your sensor:

Keep water out of the sensors by storing them with the threaded side down. Don’t pull the threaded sensors from hoses, screw them out. Use the nipple adapters to insert into hoses when possible. Use appropriate oil tube attachments to get a good, tight fit. You might have to try several different ones to get a snug fit.

-

- National Guard

- Head Gasket

- Injector Circuit

- Worn Cam and Lifter

CASE STUDIES

- Head Gasket

- Injector Circuit

- Worn Cam and Lifter

Here we show a case where the engine integrity is poor and OBD is misleading. A faulty head gasket is the problem. Thanks to Jeff Kogan for this study.

Cylinder Head Gasket.pdf : Click Here

Here we show how to use the Firstlook sensors to identify bad injectors. Thanks to Jeff Kogan of Square One Diagnostics for this write-up!

Injector.pdf : Click Here

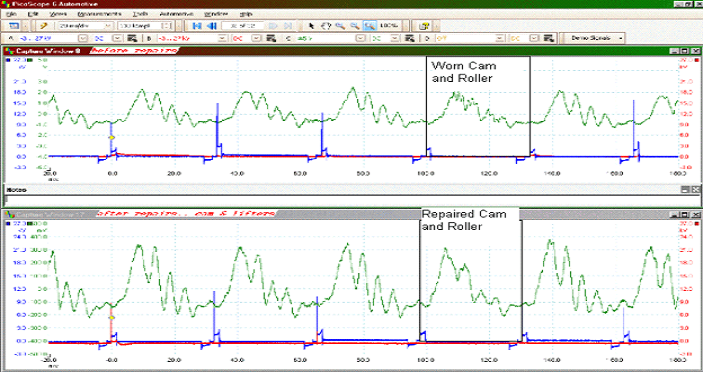

This problem was solved using the FirstLook Sensor on the intake manifold and collecting vacuum waveforms. “This mystery could not be solved without the First Look Sensor hooked up to a Pico Scope and the training and support from Tom Roberts (Autonerdz)” Wilf Breyfogle

2000 GMC Safari van, 221,000 km, 4.3L vortec

Worn cam and lifter : Click Here

-

- National Guard

- Head Gasket

- Injector Circuit

- Worn Cam and Lifter

SenX FirstLook Pulse Sensor Intro 2014

Louie Nelson provides an introduction to the FirstLook® sensor and several ways it can be used to help in diagnosis physical problems of engines. (9:36 min)

SenX FirstLook Sensor Methodology 2014

This video provides several uses for FirstLook® sensors with diesel engines – assessment and diagnostics. It is more detailed than the others. (17:26 min)

SenX FirstLook Sensor Bosch 2014

Louie Nelson demonstrates the use of the FirstLook® with a Bosch 3857 oscilloscope with an OTC Touch for automotive diagnostics of engine mechanical problems. (4:41 min)

SenX FirstLook Sensor Pico 2014

Louie Nelson demonstrates the use of the FirstLook® with a PicoSpcope Digital PC oscilloscope for automotive diagnostics of engine mechanical problems. (6:05 min)

SenX FirstLook Sensor Snap On Verus 2014

Louie Nelson demonstrates the use of the FirstLook® with a Snap On Verus oscilloscope for automotive diagnostics of engine mechanical problems. (4:46 min)

Engine Polygraph (SHM)

Introducing Engine Polygraph; what it does, how to use it and where it adds value for used vehicle dealers, maintenance shops and fleet owners. EP is also known as SenX History Manager. (8:45 min)

-

- National Guard

- Head Gasket

- Injector Circuit

- Worn Cam and Lifter

FirstLook® Quick Start

This 6-page Manual describes the steps to use the FirstLook® sensor to view the fuel volume difference delivered to the injectors; to view the cold-crank exhaust output to identify if you have ‘weak’ cylinders; to watch the exhaust pulses of an idling engine to find cylinder-specific power issues or intermittent power issues; and to spot power stroke issues from the exhaust of your engine under load.

FirstLook® Spark Plug Manual

This 38-page Manual covers 4-stroke “spark-plug” engine Assessment and Diagnosis methods. It focuses on capture and analysis of simultaneous exhaust and crankcase signatures based on cylinder offset tables unique to number of cylinders in the engine.

FirstLook® Diesel Manual

This 53-page Manual covers 2- and 4-stroke diesel engine Assessment and Diagnosis methods. It focuses on capture and analysis of simultaneous exhaust and crankcase signatures based on cylinder offset tables unique to number of cylinders in the engine.

FirstLook® Injector Manual

This is for the ADS ES 300 Automotive Injector kit (SKU 30010) for diagnosing fuel supply of many non-diesel engines with non-returning common-rail systems.

ES100 Timing Chart for 2 and 4 stroke

These two pages list the time between cylinder ignitions for engines at various speeds (rpm), depending on the number of cylinders. Also shown is the time duration of a complete 2- or 4-stroke cycle of the engine such that each cylinder should fire once. (This is a 2-page document that might be printed on both sides – one side with data for 4-stroke engines and the other for 2-stroke engines.

SenX Signature Log

A table to be used to document the vehicle and conditions for each SenX test condition run so that stored signatures can be recalled with needed context for comparison with other similar engines or the same engine over time. This might be considered a paper version of Engine Polygraph (www.enginepolygraph.com).

FirstLook® Spec Sheet

This is a FirstLook® product data sheet showing the response characteristics of the FirstLook® sensor indicating performance parameters that might be necessary to know for special applications.

-

- National Guard

- Head Gasket

- Injector Circuit

- Worn Cam and Lifter